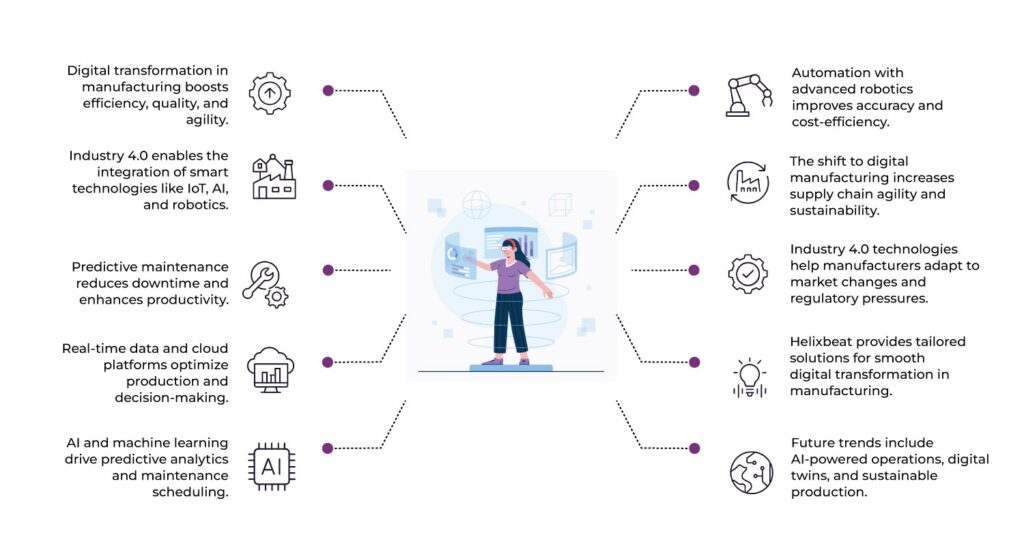

Manufacturing isn’t what it used to be—and that’s a good thing. Gone are the days when factories relied solely on manual processes and outdated systems. Today, businesses in the manufacturing sector are under pressure to produce more, faster, and with better quality, all while keeping costs down. This is where digital transformation in manufacturing steps in—not as a buzzword, but as a real-world solution to modern challenges.

The shift to Industry 4.0 marks a new era of smart manufacturing. From advanced robotics to automation in manufacturing, and from real-time data analytics to IoT in manufacturing, the tools are available to revolutionize how products are made and how factories are run. It’s not just about upgrading technology—it’s about building smarter systems that work together and adapt to change.

One of the most powerful outcomes of this transformation is predictive maintenance, which helps manufacturers prevent breakdowns before they happen, saving time, money, and headaches. These are no longer future concepts—they’re tools companies are using right now to stay competitive.

At Helixbeat, we understand the complexity of manufacturing. Our digital transformation solutions are designed to meet manufacturers where they are, helping them take confident steps toward automation, real-time insights, and long-term growth. Whether it’s scaling up operations, reducing downtime, or unlocking the full potential of your data, we’re here to help you make the shift to smart manufacturing seamlessly and successfully.

Table of Contents

What Is Digital Transformation in Manufacturing?

Digital transformation in manufacturing refers to the strategic adoption of digital technologies to improve production, optimize operations, and deliver better products and services. It is not merely about automating a few tasks—it’s about rethinking how manufacturing works from the ground up.

Core components of this transformation include:

- Smart sensors for real-time monitoring

- Cloud-based platforms for centralized data

- Artificial intelligence for intelligent insights

- Robotics and software for automated workflows

For manufacturers, this means shifting from reactive operations to predictive and autonomous systems. The transformation ensures seamless integration of machines, data, and people to enable faster decision-making and innovation.

The Urgency of Industry 4.0

We live in an era where customer expectations evolve rapidly, competition is global, and supply chains are vulnerable. In this environment, digital transformation in manufacturing is not optional—it is essential.

Industry 4.0 marks the fourth industrial revolution, characterized by the fusion of physical and digital systems. It empowers manufacturers to adapt quickly, reduce costs, and deliver consistent quality.

Manufacturers embracing Industry 4.0 can respond more effectively to:

- Demand surges

- Resource shortages

- Labor constraints

- Regulatory pressures

- Sustainability goals

This transformation ensures production is no longer confined by rigid processes but can evolve dynamically based on insights and intelligence.

Key Technologies Powering Transformation

Core Technologies Powering Digital Transformation in Manufacturing

The promise of digital transformation in manufacturing lies in the integration of next-generation technologies that work together to build smarter, faster, and more adaptive production systems. These tools are not just about automation—they form the digital backbone of Industry 4.0, reshaping everything from factory floors to global supply chains. Here’s a closer look at the most impactful technologies and how they are applied in modern manufacturing:

Internet of Things (IoT) in Manufacturing

IoT in manufacturing connects machines, devices, and systems through a network of sensors and software, enabling them to collect and share real-time data. This connectivity allows manufacturers to monitor equipment performance, track inventory, and identify inefficiencies. The result? Smarter, interconnected factories with improved operational visibility and faster decision-making.

Big Data and Advanced Analytics

As manufacturing processes generate massive amounts of data every second, the ability to make sense of it becomes a competitive advantage. Big data platforms and advanced analytics tools help businesses analyze production metrics, identify trends, and uncover insights that would otherwise go unnoticed. This leads to more informed decisions, fewer errors, and consistently high product quality.

Artificial Intelligence (AI) and Machine Learning

AI is a key driver of predictive maintenance, allowing systems to forecast when machines are likely to fail and take preemptive action. By identifying patterns in data, AI and machine learning help optimize maintenance schedules, reduce unplanned downtime, and increase overall equipment effectiveness. These systems learn and improve continuously, adding long-term value to manufacturing operations.

Automation in Manufacturing with Advanced Robotics

Modern robotics in manufacturing goes far beyond repetitive tasks. Today’s robots are capable of performing complex operations with precision and can work collaboratively with human operators. Automation in manufacturing reduces labor-intensive processes, boosts accuracy, and significantly lowers the risk of human error, enabling scalable and cost-efficient production.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR are transforming workforce training and equipment management. These immersive technologies allow teams to simulate manufacturing environments, visualize digital instructions in real time, and even conduct remote troubleshooting. The result is faster training, safer operations, and more confident technicians on the shop floor.

Cybersecurity for Smart Manufacturing

As factories become more connected, they also become more vulnerable. Protecting digital infrastructure is critical to safeguarding data, maintaining system reliability, and ensuring uninterrupted production. Robust cybersecurity frameworks are essential components of any digital transformation strategy, providing a secure foundation for innovation

Benefits of Digital Transformation in Manufacturing

The impact of digital transformation in manufacturing is tangible across multiple operational areas. Manufacturers that have embraced this shift report significant improvements in performance and resilience.

Key benefits include:

Operational Efficiency: Digital workflows, real-time monitoring, and automated systems accelerate production while reducing bottlenecks.

Cost Reduction: Energy-efficient operations, optimized maintenance, and fewer product defects translate into substantial savings.

Quality Assurance: Technologies like AI and IoT in manufacturing improve quality control, enabling real-time defect detection and process optimization.

Supply Chain Agility

With data-driven logistics and production planning, manufacturers can swiftly adapt to changing demands and market disruptions.

Sustainability: Efficient resource utilization, reduced waste, and lower emissions help companies meet environmental standards and corporate social responsibility goals.

Workforce Empowerment: Rather than replacing human workers, digital tools empower them with better data, clearer insights, and less repetitive work.

Industry Statistics: Evidence of Change

Data highlights the accelerating pace of digital transformation in manufacturing and its significant returns:

- 80% of global manufacturing firms have increased their digital investments since 2020. (Deloitte, 2023)

- Predictive maintenance reduces unplanned equipment downtime by up to 50% and lowers maintenance costs by 25%. (McKinsey)

- IoT in manufacturing has improved asset utilization by 15–25% for companies using smart sensors. (Forbes)

- Automation in manufacturing has led to a 30–40% boost in productivity in key production areas. (PwC)

- Manufacturers leading in digital maturity are twice as profitable as those lagging behind. (Capgemini Research)

These figures reflect a clear trend: digital adoption in manufacturing is not just beneficial—it is critical for long-term success.

Challenges Manufacturers Face

Despite the advantages, the path to digital transformation in manufacturing is not without obstacles:

Legacy Systems: Many factories rely on outdated equipment that lacks digital compatibility, complicating integration efforts.

High Initial Costs: Though the ROI is significant, upfront investment in digital infrastructure can deter some manufacturers, especially small and mid-sized enterprises.

Talent Shortages: New tools require new skills. Bridging the knowledge gap among staff is essential but often overlooked.

Integration Complexity: Synchronising various platforms, devices, and workflows can be technically challenging.

Cybersecurity Risks: With greater connectivity comes increased vulnerability. Securing connected systems is critical.

Helixbeat helps manufacturers overcome these barriers by offering tailored solutions, expert consultation, and implementation support at every stage of the journey.

How Helixbeat Leads the Way

Helixbeat provides a holistic approach to digital transformation in manufacturing, enabling manufacturers to move from outdated processes to data-driven, intelligent systems.

Here’s how Helixbeat supports transformation:

Strategic Consulting: Helixbeat begins with a thorough assessment of your operations and creates a customized roadmap aligned with your business goals.

IoT Infrastructure Deployment: From sensor installation to cloud analytics platforms, Helixbeat implements robust IoT in manufacturing that drives visibility and control.

Automation Implementation: Helixbeat delivers automation in manufacturing at both hardware and software levels, improving production accuracy and speed.

Predictive Maintenance Integration: By integrating predictive analytics tools, Helixbeat helps reduce unplanned downtime and extend the lifespan of machinery.

User-Centric Design: Custom dashboards and mobile platforms ensure easy access to insights, even for non-technical personnel.

Helixbeat’s solutions are designed to be scalable, secure, and future-proof—enabling long-term digital growth.

What Lies Ahead: Future Trends in Manufacturing

As digital transformation in manufacturing continues to evolve, several trends are poised to shape the future of smart factories:

AI-Powered Operations: Artificial intelligence will take a leading role in quality inspection, supply chain forecasting, and demand planning.

Digital Twins: Virtual replicas of machines and systems will allow for real-time simulations and optimisations without interrupting operations.

Sustainable Production: Digital tools will help manufacturers monitor and reduce their carbon footprints while improving resource efficiency.

5G and Edge Computing: These technologies will enable faster, real-time communication between devices, improving responsiveness and automation accuracy.

Helixbeat is actively developing solutions aligned with these trends, ensuring that manufacturers stay ahead of the curve.

Conclusion: A Smarter Future Starts Now

Digital transformation in manufacturing is no longer just a competitive advantage—it’s a necessity. In the age of Industry 4.0, manufacturers must embrace innovation to remain resilient, efficient, and agile.

With solutions focused on automation, IoT, and predictive maintenance in manufacturing, Helixbeat is helping manufacturers future-proof their operations. Whether it’s reducing downtime, improving product quality, or gaining actionable insights, the path forward is digital.

Helixbeat stands ready to guide manufacturers through this journey—delivering not only the tools but the strategy to thrive in the new industrial era.

FAQs

What is digital transformation in manufacturing?

Digital transformation in manufacturing refers to the integration of digital technologies like IoT, AI, and automation to optimize production and operations.

Why is Industry 4.0 important for manufacturers?

Industry 4.0 enables manufacturers to become more efficient, agile, and competitive by leveraging data-driven, smart technologies across the production chain.

How does IoT impact manufacturing?

IoT connects machines and systems, allowing real-time monitoring and data sharing, which enhances equipment efficiency, quality control, and decision-making.

What are the benefits of automation in manufacturing?

Automation reduces manual effort, minimizes errors, boosts accuracy, and increases scalability, leading to faster and more cost-effective production.

How does AI contribute to predictive maintenance?

AI analyzes patterns in machine data to forecast potential failures, allowing for timely maintenance and reducing unexpected downtime and costs.

Is digital transformation only for large manufacturers?

No. Small and mid-sized manufacturers can also benefit by adopting scalable digital solutions tailored to their specific needs and budgets.

What challenges come with digital transformation in manufacturing?

Key challenges include legacy system integration, high upfront costs, workforce training needs, cybersecurity risks, and complex system synchronization.