Visitor tracking software helps you keep track of everyone who comes into your factory. In many manufacturing sites, delays at the front desk can slow down work, hold up shipments, frustrate staff, and even create safety risks. Studies show that using old manual systems can make check-ins up to 40% slower and increase the chances of mistakes or compliance problems.

Many factories still rely on paper logs or old digital tools that are hard to update, hard to connect with other systems, and don’t grow with the business.

Modern visitor tracking software fixes all this. It makes check-ins faster, keeps accurate records, improves safety, and helps you follow rules easily. It makes your operations smoother and more secure making sure every visitor is managed the right way, every time.

Table of Contents

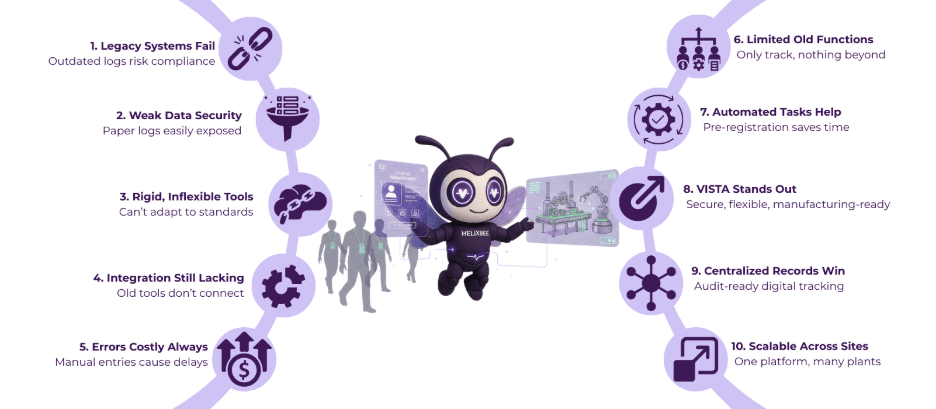

Why Legacy Systems Are Holding You Back

Legacy systems, such as paper logbooks or outdated digital software, were useful once—but they weren’t designed for today’s fast-paced, high-security manufacturing environment. Here’s where they fall short:

1. Poor Data Security

Paper logs are easy to tamper with and difficult to track. If a contractor or vendor logs in, how do you know they’re cleared for a restricted zone? Even older digital tools can store information locally, creating potential security gaps and making compliance reporting tedious.

With modern visitor tracking software, every entry is logged digitally and securely. VISTA, for example, ensures real-time verification and keeps track of all visitor movements, providing a secure environment for both employees and visitors.

2. Limited Flexibility

Manufacturing regulations and safety standards aren’t static—they change. Legacy systems are rigid, making it challenging to adapt. Whether it’s OSHA updates, ISO certifications, or new internal safety protocols, outdated systems can’t propagate updates across multiple locations efficiently.

A robust Visitor Management System like VISTA is designed for flexibility. It allows you to implement policy updates instantly, across all your manufacturing sites. This ensures compliance, reduces risk, and saves valuable time.

3. Integration Challenges

Old systems often don’t communicate with your other tools. Safety logs, ERP platforms, and access control software remain siloed. This forces manual checks, duplicate data entry, and extra work for your staff.

Integrating visitor check in software with your existing systems not only streamlines operations but also ensures data consistency. VISTA integrates seamlessly with enterprise platforms, allowing you to track, approve, and analyze visitor data from a single interface.

4. Manual Errors Are Costly

Manual systems rely heavily on human intervention. A single missed check-in can halt production or cause compliance violations. Paper logs are prone to mistakes, illegible handwriting, or lost documents.

Modern visitor tracking software automates these processes. VISTA minimizes errors by digitizing visitor entry, approvals, and reporting, allowing your team to focus on production rather than paperwork.

5. Limited Functionality

Old systems were built for a single purpose: recording who comes and goes. Today’s manufacturing facilities need multifunctional solutions. You require tools that can:

- Verify vendor credentials

- Flag restricted access areas

- Store compliance documents

- Prepare reports for audits

VISTA is more than just a visitor management system USA manufacturers can rely on. It’s a comprehensive platform that covers multiple workflows, reducing dependency on multiple software tools.

Upgrade to 21st Century Visitor Management

Modern visitor tracking software is no longer a digital sign-in sheet—it’s a full-fledged platform connecting people, data, and facility security. Here’s what a modern upgrade offers:

1. Automate Routine Tasks

Stop chasing emails or printing forms. Visitor check in software automates routine tasks like sending pre-visit compliance forms, safety guidelines, and PPE requirements. Contractors and vendors can pre-register and complete required training digitally before arriving on-site.

This automation reduces bottlenecks and allows employees to focus on what truly matters: production and safety.

2. Streamlined Visitor Workflow

Forget last-minute scrambling at the gate. With VISTA, every visitor is pre-verified, briefed on plant safety protocols, and ready to move through entry points without delays. A streamlined workflow not only improves visitor experience but also ensures adherence to safety standards.

This makes VISTA the best visitor management system for manufacturing environments, where time is money and efficiency is paramount.

3. Centralized Records and Full Visibility

Imagine a system that stores all visitor data across all your sites. With modern visitor tracking software, managers can generate reports, identify trends, and audit compliance with ease.

- Spot bottlenecks at security desks

- Identify missed safety acknowledgments

- Track unusual activity patterns

Centralized records make audits easier and allow you to strengthen security proactively. VISTA’s robust analytics provide actionable insights that help prevent incidents before they occur.

4. Enhanced Security and Compliance

Every missed check-in or manual log is a potential compliance violation. Modern Visitor Management System solutions like VISTA track visitor movements in real-time, send instant host notifications, and provide emergency evacuation lists.

This ensures that your site complies with local and international safety standards while keeping employees and visitors safe.

5. Scalability Across Multiple Sites

As manufacturing facilities expand, so do the challenges of visitor management. Legacy systems fail when operations scale, but modern visitor check in software is built to handle growth.

VISTA can manage multiple sites from a single platform, giving your security teams a consistent, streamlined process across locations. This ensures that compliance, security, and efficiency don’t suffer, even as visitor numbers grow.

6. Real-Time Analytics for Smarter Decisions

Modern visitor tracking software doesn’t just track visitors—it provides data-driven insights. VISTA’s analytics dashboard lets you monitor high-traffic periods, optimize resource allocation, and even identify patterns of unusual behavior.

Decision-makers can use this information to enhance security protocols, improve workflow, and maintain compliance effortlessly.

7. Mobile and Touchless Check-Ins

In a post-pandemic world, touchless entry isn’t just a convenience—it’s a necessity. VISTA allows visitors to check in via QR codes, mobile apps, or facial recognition, reducing physical contact and ensuring a safer environment.

This feature also accelerates the entry process, making VISTA a true best visitor management system for modern manufacturing sites.

8. Emergency Preparedness

Safety is non-negotiable. Whether it’s a fire drill or an actual emergency, modern visitor tracking software ensures you have a complete record of who’s on-site. VISTA generates evacuation lists instantly and guides staff to secure zones, ensuring no one is left behind.

Why VISTA Stands Out in Manufacturing Sites

In a busy manufacturing site, keeping track of visitors is more than just signing people in. Every visitor—whether a contractor, vendor, or guest—needs to be monitored for safety, security, and smooth operations. That’s where VISTA visitor tracking software comes in. It’s designed to make visitor management simple, fast, and reliable.

1. All-in-One Features

VISTA is not just a digital logbook. It has everything a manufacturing site needs:

- Pre-Registration: Visitors can be registered before they arrive. Contractors can upload documents, safety certifications, and approvals in advance.

- Real-Time Tracking: You can see exactly where each visitor is in the facility at any time.

- Instant Alerts: Hosts are notified immediately when a visitor arrives, reducing delays.

- Reports and Analytics: Get insights on visitor patterns, peak hours, and safety compliance to make better decisions.

With these features, VISTA keeps visitor management organized and efficient, which is vital for busy manufacturing operations.

2. Easy Integration with Other Systems

Manufacturing facilities use many systems like ERP, MES, and access control software. VISTA works smoothly with these tools.

- Vendor information from ERP can automatically update access permissions.

- Safety compliance data from MES can be linked to visitor check-ins.

- Everything is connected, reducing mistakes and saving time.

This makes VISTA one of the most trusted visitor management systems in the USA.

3. Simple and User-Friendly

VISTA is easy for both visitors and employees:

- Visitors can check in using kiosks, mobile apps, QR codes, or facial recognition.

- Employees can approve visitors, send alerts, and access reports with just a few clicks.

- No long training sessions needed; everyone can use it easily, even on a busy day.

4. Works for One Site or Many

Whether you have one factory or multiple plants, VISTA can handle it:

- Manage visitors from a single dashboard.

- Apply the same rules and access controls across all locations.

- Add new sites without extra hassle.

This scalability makes it perfect for growing manufacturing companies.

5. Strong Security and Compliance

Security is crucial in manufacturing: restricted areas, sensitive machines, and valuable equipment all need protection. VISTA helps by:

- Tracking every visitor in real time.

- Keeping digital records for audits and compliance.

- Creating emergency evacuation lists instantly.

- Checking credentials, safety training, and PPE compliance before anyone enters.

6. Trusted by Global Manufacturers

VISTA is recognized worldwide as a reliable and best visitor management system. Manufacturing companies in the USA and other countries trust it to manage visitors safely and efficiently.

7. Saves Time and Money

Automating visitor processes reduces delays, prevents errors, and cuts down on extra administrative work. Employees can focus on production, and the facility runs more smoothly.

8. Flexible and Modern

VISTA works with cloud-based or on-premise setups and supports mobile devices, kiosks, and touchless options. It adapts to your site’s needs, making visitor management modern and easy.

In short, VISTA is more than just a visitor management system. It’s a simple, smart solution that keeps manufacturing sites safe, organized, and efficient.

Conclusion

Manual and outdated visitor processes are no longer viable in today’s manufacturing landscape. They introduce risks, slow operations, and limit growth. Modern visitor tracking software, like VISTA, bridges the gap—enhancing security, ensuring compliance, and improving operational efficiency.

Upgrade now to automate check-ins, streamline visitor flow, gain full visibility, and future-proof your manufacturing site. Don’t let your front desk remain a bottleneck while your production line runs on automation

FAQs

1. What is visitor tracking software and why is it important for manufacturing sites?

Visitor tracking software digitally records and monitors all visitors entering a facility. It helps improve security, compliance, and operational efficiency in manufacturing environments.

2. How can visitor management software improve operations in factories?

It automates check-ins, tracks visitors in real-time, integrates with existing systems, ensures compliance, and provides centralized reports for multiple sites.

3. Can visitor management software handle multiple manufacturing sites?

Yes. Modern software is scalable and allows management of visitors across one or multiple sites from a single dashboard, applying consistent rules and access controls.

4. How does visitor tracking software enhance security and compliance?

It verifies credentials, tracks visitor movements in real-time, keeps digital records for audits, and generates emergency evacuation lists to maintain safety and compliance.

5. Does visitor management software support touchless or mobile check-ins?

Yes. Visitors can check in using mobile apps, QR codes, kiosks, or facial recognition, making the process faster, safer, and contactless.