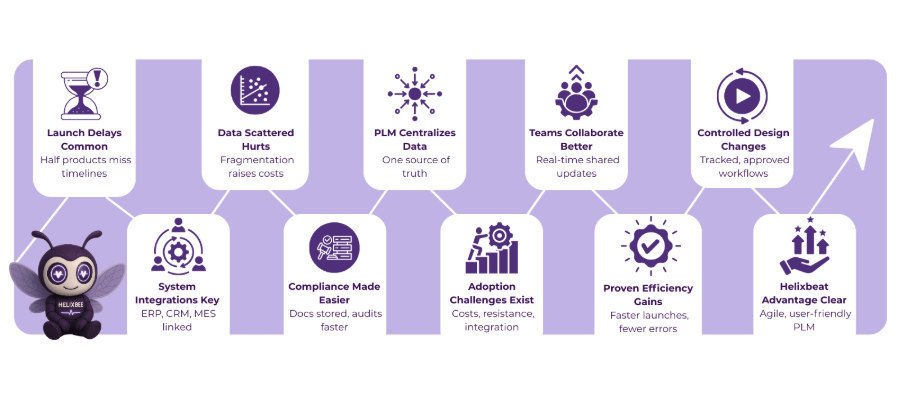

Did you know that almost 1 out of 2 product launches gets delayed? Additionally, companies often spend 20–30% more money because their product data is scattered across multiple locations. This slows everything down and makes work harder.

The primary issue is that teams often fail to collaborate effectively. Designers, engineers, marketing, and supply chain teams often use separate systems. This causes confusion, mistakes, and delays.

The solution is to bring everything into one system. That’s what product lifecycle management (PLM) does. It connects teams, keeps data in one place, and makes the whole process smoother. With product lifecycle management software, businesses can save time, reduce costs, and avoid errors.

And with agile product lifecycle management, companies can also adapt quickly when plans change. Let’s see in detail how you can organize your operation with effective product lifecycle management.

Table of Contents

Why Product Lifecycle Management is Important for Businesses?

Managing a product from the idea stage to its retirement is not easy. Different teams like engineering, supply chain, and quality control often work separately, which creates confusion. Important files such as designs, bills of materials (BOM), and compliance reports may get lost or duplicated.

A study in 2023 showed that companies using product lifecycle management (PLM) cut the time needed to handle design changes by almost 35%, which means faster launches and lower costs.

With product lifecycle management software, all product information is stored in one system. This makes it easier to track changes, manage approvals, and keep everything updated.

How Product Lifecycle Management Organizes Business Operations

Product lifecycle management is more than just a tool; it’s a framework that helps businesses bring order, speed, and clarity into everyday operations. Here’s how it makes a real difference:

1. Keeping All Your Product Data in One Place

In most companies, product information is scattered with design files in one system, quality reports in another, and spreadsheets on different computers. Product lifecycle management (PLM) solves this by bringing everything into one system. Everyone works with the latest version, which reduces mistakes and saves time.

A 2023 survey by CIMdata showed that companies with centralized PLM reduced data errors by over 25%.

2. Helping Teams Work Together Smoothly

When design, engineering, and supply chain teams work separately, projects slow down. PLM creates a shared space where all teams can see updates in real time. For example, if the design team makes a change, the production team can act on it right away. This cuts delays and improves collaboration.

Research by Tech-Clarity found that PLM improves cross-team collaboration efficiency by up to 30%.

3. Making Design Changes Easy to Control

Uncontrolled design changes can create big problems. With product lifecycle management software, every change is tracked, reviewed, and approved through a clear workflow. This means fewer errors, less rework, and a proper record of who approved what, making the whole process more reliable.

Aberdeen Group reported that companies using PLM cut engineering change order cycle times by 35% on average.

4. Connecting with Other Business Systems

Your product data shouldn’t stay locked in one department. Modern PLM tools connect with ERP, CRM, and MES systems, so updates flow automatically across the company. With agile product lifecycle management, businesses can quickly adjust to customer feedback or changes in the market.

A 2022 PwC study revealed that integrated PLM-ERP systems improved supply chain responsiveness by 27%.

5. Making Compliance Less Stressful

Passing audits and following regulations can feel overwhelming. PLM makes it easier by keeping all certifications, test reports, and compliance documents in one place. This helps businesses avoid penalties, reduces the risk of recalls, and makes it faster to clear inspections.

According to IDC, PLM-enabled compliance tracking reduces audit preparation time by 40%.

Together, these benefits show how Helixbeat product lifecycle management gives businesses the control, flexibility, and visibility they need to run operations more efficiently and bring products to market faster.

What are the Challenges in Product Lifecycle Management

While product lifecycle management (PLM) brings many benefits, businesses often face hurdles during adoption and execution. Here are some common challenges:

1. Data Fragmentation Across Systems

One of the biggest challenges is that product data often lives in different places: design tools, spreadsheets, emails, and ERP systems. This fragmentation makes it hard to maintain a single version of the truth. Without a unified system, teams may rely on outdated files, leading to costly errors.

A 2023 Tech-Clarity study found that 41% of manufacturers struggle with inconsistent product data across departments.

2. High Implementation and Maintenance Costs

Setting up a PLM system can require a large upfront investment in software, training, and infrastructure. For smaller businesses, this becomes a barrier. Even after deployment, maintaining licenses, integrations, and upgrades can add ongoing costs.

Research by Gartner (2022) showed that nearly 28% of PLM projects face budget overruns due to underestimated implementation costs.

3. Resistance to Change Within Teams

Employees often resist shifting from their familiar tools and workflows to a new system. Design and engineering teams may worry about losing control over their processes, while others may see PLM as “extra work.” Overcoming this cultural barrier requires strong change management and leadership support.

Deloitte’s 2022 report highlighted that over 35% of digital transformation projects fail due to user resistance.

4. Integration Complexity with Existing Tools

Modern businesses run on multiple systems like ERP, CRM, MES, and supply chain software. Integrating PLM with these tools is often complex, requiring customization and technical expertise. Poor integration can slow down processes instead of improving them.

According to IDC (2023), 30% of companies face delays in PLM adoption because of integration challenges with legacy systems.

Overcoming these challenges is possible with the right strategy. Solutions like Helixbeat product lifecycle management focus on user-friendly design, cost efficiency, and seamless integration, making it easier for businesses to unlock the real value of PLM.

Benefits of Using Product Lifecycle Management Software

Using product lifecycle management software gives businesses more than just a tool; it creates a structured way to reduce risks, improve collaboration, and get products to market faster. Here are some of the key benefits:

- PLM software creates a shared space where engineering, design, supply chain, and marketing teams can work together. Everyone sees the latest updates in real time, which reduces communication gaps and project delays.

- With streamlined workflows and automated approvals, businesses can shorten the product development cycle. This means products launch faster, giving companies a competitive edge.

- Every design change is logged, reviewed, and approved systematically, reducing rework and improving product quality. This ensures traceability across the entire product lifecycle.

- PLM connects smoothly with ERP, CRM, and MES platforms, ensuring that updates in one system automatically reflect in others. This integration supports agile product lifecycle management, allowing businesses to adapt quickly to market changes.

- PLM software stores all certifications, audit reports, and compliance documents in one place. This makes audits easier and reduces the risk of penalties or recalls.

See How It Works with a Real Example

In 2022, Siemens used product lifecycle management software to streamline its operations for industrial equipment manufacturing. Earlier, their teams faced delays because design changes were not reaching production quickly. This caused rework, higher costs, and slower delivery by adopting an agile product lifecycle management approach. Siemens connected design, engineering, and supply chain teams in real time.

With the new system in place, changes in product designs are automatically updated across ERP and manufacturing systems. This reduced errors, improved compliance tracking, and sped up decision-making. As a result, Siemens was able to bring products to market more quickly while reducing operational costs.

This shows how Helixbeat product lifecycle management can also help businesses create the same level of efficiency and visibility across their product journey.

Why Choose Helixbeat Product Lifecycle Management?

At Helixbeat, we know that managing a product from start to finish can be tough when different teams and systems don’t work together. Our product lifecycle management software streamlines this process by consolidating all your product data in one place, facilitating real-time collaboration among teams, and minimizing errors through clear change tracking.

We follow an agile product lifecycle management approach, which means your business can adapt quickly to customer needs, market changes, or new rules without slowing down. No matter if you’re in manufacturing, healthcare, automotive, or technology, Helixbeat product lifecycle management gives you the control and flexibility to launch better products faster and at lower cost. Book a free consultation call with us.

FAQ

1. How long does it take to implement PLM software?

The time it takes to implement PLM software depends on the complexity of your product lines and the specific software you choose. On average, it can take anywhere from 3 to 12 months for a full deployment. Factors like data migration, system integration, and employee training all play a role in the timeline.

2. How can PLM software help with sustainability efforts?

PLM helps with sustainability by allowing businesses to track the environmental impact of their products throughout their lifecycle. By managing material usage, energy consumption, and waste more efficiently, PLM helps businesses make greener choices during design, manufacturing, and product disposal.

3. What industries benefit most from using PLM software?

Industries like automotive, aerospace, electronics, and pharmaceuticals benefit greatly from PLM software due to the complexity and high regulatory requirements in these sectors. However, any industry involved in product design, production, or innovation can use PLM to improve efficiency and reduce time-to-market.

4. What are the three best PLM companies in India?

Siemens Digital Industries Software, Dassault Systèmes, and Helixbeat are leading PLM companies in India. Siemens and Dassault offer advanced solutions for large enterprises, while Helixbeat specializes in agile, user-friendly PLM software for small and medium-sized businesses.

5. Can PLM help improve product quality?

Absolutely. PLM enables businesses to track and manage every detail of a product’s lifecycle, ensuring that design, manufacturing, and quality control teams work from the same set of data. This reduces errors, improves traceability, and ultimately enhances product quality.